How to Fulfil Dropship Orders: A Complete Guide for Suppliers and Dropshippers

When you order an item online, you set off a chain of processes and procedures that help to ensure your product arrives as it’s intended. This chain of events is a fulfillment process, and it is an aspect of ecommerce that can make or break a business.

The global pandemic exposed flaws across many supply chains. Labour shortages made it difficult for not only B2C deliveries, but for the procurement of raw materials. The abrupt shift in customer behaviour left stores struggling to manage inventory effectively. Shipping demands have created a backlog that is not expected to abate before 2023 at the earliest.

According to the Shopify Future of Commerce Trend Report 2022, customer expectations for delivery have only risen in the past few years:

-

Free shipping continues to have a significant impact on purchasing for 75 per cent of global shoppers.

-

When packages are delayed but customers are not informed, 69.7 per cent of customers are less likely to shop with that retailer again.

-

56 per cent of shoppers moved away from their preferred retailer because they could not get timely delivery.

-

68 per cent of customers find free returns and estimated arrival times valuable factors when searching and buying online.

This goes with saying, order fulfillment is one of the most important aspects of an ecommerce business. Customers expect more than ever from online retailers, and they aren't afraid to turn to the competition if their preferred brands cannot deliver - literally and figuratively. That’s why more businesses are looking for an alternative fulfillment method, including dropshipping fulfillment.

What is dropshipping order fulfillment?

The fulfillment process occurs immediately after a customer makes a purchase and continues until it arrives at the door. Along the way, this sets off a chain of events to not only get the product to its final destination but keep it from coming back through the returns funnel. This chain of events includes receiving products at the warehouse, long-term inventory storage, packaging products, and weighing products for shipping.

Dropshipping is a commonly used method to manage order fulfillment. With dropshipping, the retailer doesn’t keep items in stock. Instead, they will buy the product from a supplier at a wholesale price. Once their customer orders the product, their dropship supplier will then fulfill dropship orders.

Essentially, a dropshipper doesn’t own any inventory, so there is no inventory to manage. Dropshipping suppliers own the fulfillment process, while the dropshipping retailer is responsible for customer service. There needs to be clear communication between all parties to make sure orders arrive on time, returns can be processed, and customers end their purchasing journey on a positive note.

How dropshipping fulfillment works

There are three main players in the dropshipping supply chain:

-

Manufacturers: The creators. The most affordable way to source products is to buy directly from the manufacturer, but they don’t often sell directly to the public, instead selling to suppliers or retailers. This is B2B.

-

Suppliers: The facilitators. Suppliers buy directly from manufacturers and sell to retailers at a slight markup, taking into consideration their cost of doing business. As with manufacturers, suppliers often won’t sell to the general public, only to retailers. This is B2B.

-

Retailers: The marketers. Retailers generally sell online to the general public or the end customer. This is B2C.

Dropshipping is appealing to retailers because it doesn’t require a storefront, warehouse, or any physical inventory. Retailers can operate on a single or several sales channels, and save on inventory, fulfillment and labour costs. The job is to market and sell the product. Meanwhile, the dropshipping supplier benefits from the opportunity to grow their customer base. As they fulfill and dropship orders, they get their products exposed to new markets. It just makes sense.

So, how does the fulfillment process work with a dropshipping model?

-

The customer places an order with the retailer.

-

The retailer places the order with the manufacturer or supplier.

-

The manufacturer or supplier picks, packs and ships the order.

-

The retailer forwards shipping information to the customer.

-

The customer receives the product.

Of course, things don’t always go smoothly. If the customer places an order and they're dissatisfied with the product received for any reason, they may request a return from the retailer. The retailer will then begin the return process with the supplier according to their policies. At this stage, the retailer should be provided with a Return Merchandise Authorisation (RMA) number that they will then pass on to the customer, along with instructions on how and where to ship the product back to the supplier. The retailer may also need to send prepaid shipping labels or packaging, and/or get a tracking number. When the package arrives at the supplier’s warehouse, they will either send a replacement product or issue a refund to the retailer’s account, and then the retailer refunds the customer. Sometimes, retailers may choose to refund the customer before getting the refund from the supplier.

What are the common challenges with fulfillment?

Customer satisfaction depends on the fulfillment method, so getting your supply chain right is essential. Unfortunately, there are things that can go wrong along the way, and they are largely out of any one party’s control.

Global supply chain crisis

COVID-19 is just one of the catalysts behind the ongoing global supply chain crisis. The Russia-Ukraine conflict, for example, has impacted not only the cost of fuel, gas and raw materials but has also caused further disruptions to an already strained shipping supply chain. Companies also have to contend with the global climate crisis, which has a variety of different effects on the supply chain including environmental disruptions (flooding, fire, extreme weather), security of supply, changing demands for products and services, and a demand for more sustainable fulfillment services.

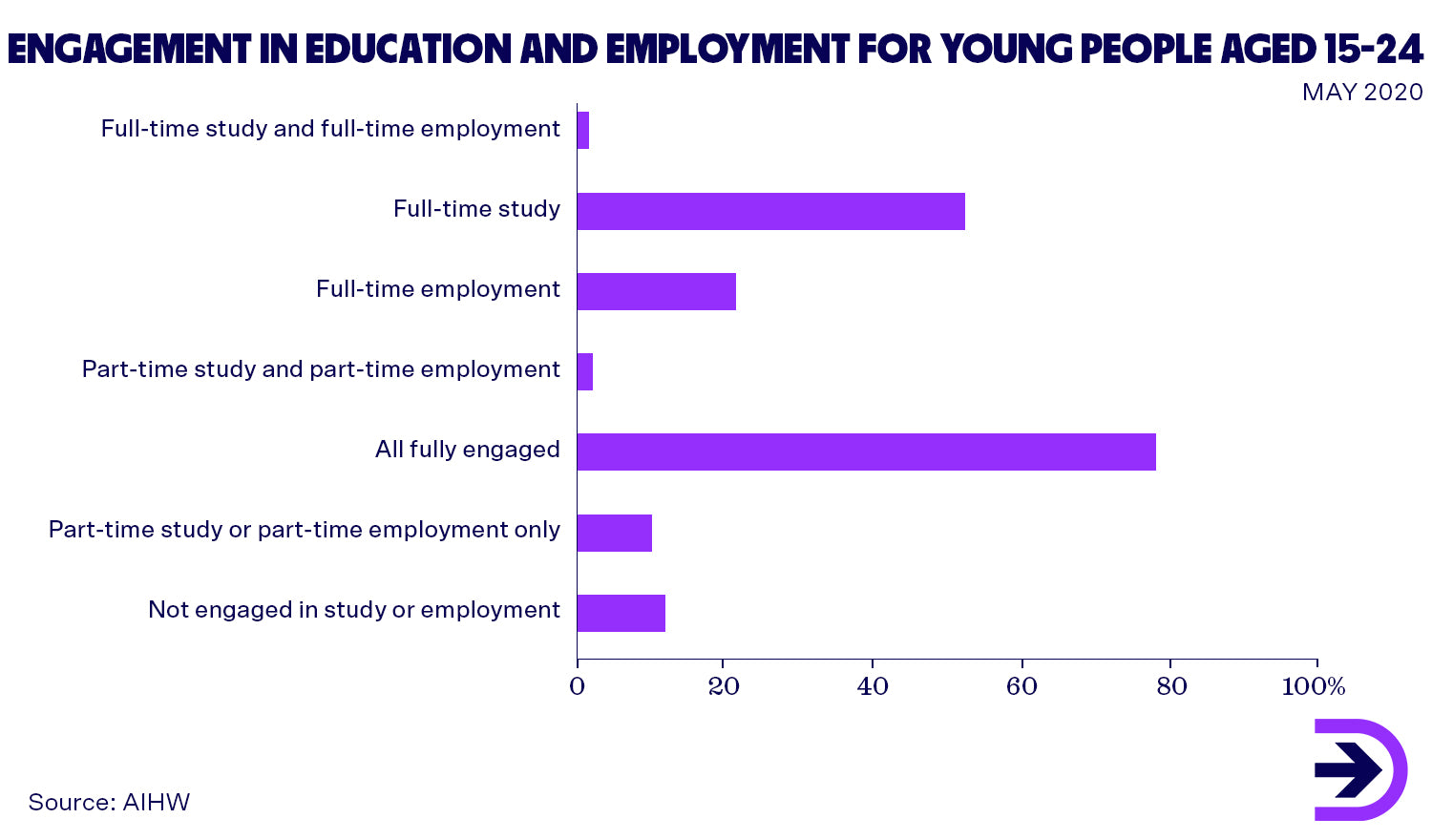

Labour shortages are another challenge impacting all areas of the supply chain. The current workforce is ageing out, but the workforce is not being replenished by young workers at the same rate. In 2020, the population of young Australian people who were considered NEET (not in employment, education or training) reached 12 per cent - the highest level in 16 years. This can be attributed in part to the psychological and physiological stress of the pandemic, but the general attitudes of younger people towards work have also shifted. Millennials and increasingly Gen Z are looking for jobs with more flexibility, higher pay, and a better work-life balance. Creating work environments that appeal to young people will be important in the coming years, while increasingly automated supply chains will help to lessen the pressure on the current workforce.

Tech integration

With so many moving parts to order fulfillment, it is crucial that you have a full picture of the business at all times, from your available stock to tracking data. Integrating your existing retail systems into your supply chain can be a daunting task even for the more tech-savvy of business owners, but it is a necessary investment.

With dropshipping fulfillment, you’re essentially solving for a crop of challenges that may arise when it comes to tech integration. Dropshipping fulfillment is typically a matter of ‘plug and play’ where you integrate with a data feed or API from a supplier, which should in turn help you keep across available inventory.

Slow shipping speeds

No matter how on top of the order fulfillment process you are, shipping can be a huge hassle, especially if you have shipping location constraints. The best way to deal with this is to have multiple warehouses in every country where you sell products.

The next best solution is to be transparent with customers about shipping times. Promising undeliverable shipping times will lead to disappointed customers and increased return rates. Be realistic about shipping times and offer compensation in the form of free shipping, lower prices than the competition, or an agreeable returns policy. Studies have shown that customers are much more willing to wait for deliveries when shipping is free.

Shipping expectations

Speaking of free shipping, it is quickly becoming an expected part of B2C ecommerce rather than a perk. 75 per cent of customers expect free shipping with an online purchase. While ecommerce giants like Amazon can afford it, small or emerging businesses may have a harder time meeting this expectation.

One way that retailers may choose to subsidise free shipping is by increasing prices, provided they can maintain their competitiveness that way. Alternatively, retailers may only offer free shipping on orders over a certain amount, or orders with two or more items. Before opting for a free shipping strategy, make sure you understand the different factors that influence shipping costs as well as the different types of shipping strategies available.

Backorders

A backorder occurs when there are more orders for an item than there is inventory. While new inventory will arrive eventually, most customers don’t want to wait for it to arrive, especially if they can get the same product from a different supplier. There are several ways to prevent this. Firstly, you can use more than one supplier to fulfill orders - if one supplier is out of stock, you can approach the other one. Secondly, you can look at your purchase history and determine when this product may be in higher demand, such as inflatable pools in summer. At the very least, fully-integrated order fulfillment software will give you a good idea of your supplier’s stock levels at any point in time, so you can see where and when there may be a backlog.

Returns

Sometimes orders go awry and the customer receives a faulty or incorrect product. Or, the customer may just change their mind. Whatever the case, retailers will find themselves having to deal with the returns process.

When choosing a supplier, retailers should become familiar with their return policies. Some dropshipping suppliers won’t offer return postage for defective items, since they are not the manufacturer, but they might pay for the replacement. Others may charge restocking fees for returned products. Before using any particular platform or marketplace, retailers should get familiar with their policies, terms and conditions.

The best way to deal with returns is to go above and beyond for the customer. First, have a clear and accessible returns policy. 67 per cent of online shoppers check a business’ return policy before purchasing an item. Secondly, offer free returns where possible, especially in the case of incorrect or defective items. If the item would cost more than it’s worth to ship back, send a replacement and let the customer keep both products instead. The customer will be less inconvenienced and get their replacement product faster than if they went through the returns process, and they may be pleasantly surprised by your generosity. Finally, offer great customer service by replying to any queries promptly and answering any questions they may have.

Fulfilling orders as a dropship supplier

When you become a dropshipping supplier, you first need to consider whether you have the capacity to hold and fulfill dropship orders in a timely manner. Unlike dropshipping retailers, you’ll need a warehouse to store your stock, and the infrastructure to fulfill lots of small orders as opposed to bulk selling. In addition to space considerations, you may like to consider things like climate control and security to keep your products protected. You’ll also need to figure out a way to keep track of your products and pass that data on to your retailers. This may look like inventory management software, which can provide real-time inventory tracking and assist with inventory audits. With the right technology, many aspects of this process can be automated. You may also like to automate the process of receiving orders and sending confirmations and invoices, making it easier to manage the many orders passing through your business each day.

Next, you’ll need an effective picking and packing process. Picking directly impacts customer satisfaction. If an order is picked incorrectly, the customer may receive the wrong product. In that case, both you and your retailer will foot the cost of return postage, refunds, and restocking fees.

Last but not least, you’ll want to find a courier partner that can handle the volume of business generated by your online store. View this as a long-term partnership, where over time, you’ll build up enough trust to negotiate lower shipping costs and pass the savings on to your retailers. You’ll also need to create a shipping policy that works for both your business and your retailers - something that is cost-effective, transparent, and easy to understand.

For more information and an in-depth look at the order fulfillment process, check out our blog Understanding Ecommerce Fulfilment.

Fulfilling orders as a dropshipper

Much of the appeal with dropshipping is having the fulfilment process managed by a third party, so you won't have to worry about these processes as much as a supplier. However, it helps to know the fulfillment process inside and out, including how your supplier manages their part of the bargain, so you know what to expect when your customer makes a purchase. It’s important to get familiar with how long the entire process takes end-to-end, which courier your supplier uses, who is involved when something goes wrong, and so on.

A dropshipper will usually only be responsible for the shipping and returns aspects of fulfillment, though the level of involvement is pared back compared to suppliers. As a dropshipper, you will need to have shipping and returns policies that are separate from (but may be based on) your suppliers. You may choose your own courier for shipping, or you may use the one offered by your supplier. Sometimes, the latter will net you a better deal, leaving extra money in the budget for offering free or flat shipping costs.

The easiest way for a dropshipper to handle order fulfillment is to use an integrated platform such as Dropshipzone. With Dropshipzone, you can see at a glance your current orders, invoices and suppliers’ inventory levels, among other information you might need for a successful order and a satisfied customer.

Summary

Ecommerce fulfillment is a complicated series of processes that all need to come together for a business to successfully operate an online store. Luckily, there are many ways that you can manage these processes to create a seamless supply chain and get your products into the hands of customers.

As the leading B2B dropship marketplace in Australia, Dropshipzone knows the importance of a working supply chain. Helping businesses start and scale since 2012, thousands of local Aussie retailers choose Dropshipzone to help facilitate their fulfillment process from warehousing to shipping. With no membership or subscription fees, you can get your dropshipping business up and running within 24 hours.Our account managers are available at any time to assist, and our integrated Shopify app allows you to instantly sync your products, inventory and orders, as well as automatically calculate shipping fees. Your ecommerce dreams are only one click away: Get started with Dropshipzone today.

FAQs

What are the benefits of using dropshipping as a fulfillment method?

If you’re wondering whether dropshipping is right for you, here’s a quick summary of the benefits of using dropshipping as a fulfillment method:

-

It has low upfront costs, making it suitable for new and small businesses.

-

Suppliers control the manufacturing and fulfillment logistics, while dropshippers only have to handle marketing, sales and customer service.

-

It’s flexible and scalable. Dropshippers can sell a wide variety of products and scale the business as they see fit. It’s an ideal model for testing new markets and niches.

-

For manufacturers and wholesalers, offering dropshipping is a great way to increase your customer base and expose your products to new markets.

What are the downsides of dropshipping fulfillment?

When dropshipping, you have less control over product quality and fulfillment while running your online store. You may also have lower profit margins compared to traditional retail.

While small margins can be mitigated with marketing, not owning the order fulfillment process can have its downsides. Firstly, many dropshipping suppliers will source their products internationally, so shipping times are more likely to be long. With more customers expecting fast shipping, this can present a problem. Fortunately, this can be combated in several ways:

-

Be transparent about shipping times. Don’t be afraid of hiding the long wait - a customer interested in the product may buy regardless of wait time.

-

Offer free or reduced shipping. 88 per cent of customers are more willing to purchase from ecommerce stores that offer free shipping, according to some studies.

-

Sell products that are unique, hard to find, or fit an exclusive niche. People will be more willing to pay for these products regardless of shipping times if they are unable to find what they want locally.

-

Use local suppliers with warehouses located in the countries where you want to ship to. This cuts back on shipping time and costs.

One of the best ways to overcome the downsides of dropshipping order fulfillment is to integrate with a B2B dropship marketplace. This is a shortcut to finding the right supplier. B2B marketplaces help improve the order fulfillment process for dropshipping suppliers and retailers – provided they have the right foundations. That’s why we make sure every supplier on Dropshipzone holds stock locally in Australia. This means the stock will ship faster from the supplier to the customer.

How do I plan my fulfillment strategy?

The best tip for planning your order fulfillment strategy for your online store is to be organised. The best processes are quick, simple, efficient, and affordable. The key to getting there is knowing your business needs, and customer needs, inside and out. Here are some of the top tips from the experts at Dropshipzone:

-

Automate as many processes as possible across your ecommerce business. This frees up your time to manage other parts of the business, as well as saving on labour.

-

Figure out where your customers are, and meet them there. This might mean using multiple warehouses or choosing suppliers local to your target market. It may also mean using an order fulfillment center.

-

Use ecommerce order fulfillment software that integrates with your existing ecommerce platform.

-

Set your KPIs early. These will clarify your business goals and help you collect hard data to measure your success. Some early KPIs might involve customer satisfaction, delivery times, order cycle times (how long an order takes to process), inventory accuracy, or picking accuracy. Choosing the right KPIs will help you see where the business is flourishing, or where you may need to tighten up your processes.

-

When in doubt, consult the experts. Whether you want to talk to an experienced dropshipping supplier or 3PL consultant, you’ll find plenty of professionals from order fulfillment companies willing to offer advice.

For more information, read our blog Understanding Ecommerce Fulfilment which details how you can set up the best dropshipping fulfillment plan for your business.

Ready to get ship done? If you're interested in scaling your ecommerce business, you can get started as a retailer with Dropshipzone in just a few clicks.